Directional / Horizontal Drilling

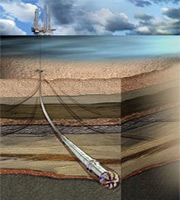

Directional Drilling is the science of deviating a well bore along a planned course to a subsurface target whose location is a given lateral distance and direction from the vertical. It is typically applied where the reservoir is trapped in an inaccessible location. Directional/Horizontal Drilling has many advantages that make it a widely used process. With an advancement of technology Directional Drilling has become more efficient which ultimately decreases the operational cost. There are multiple techniques of drilling directional wells such as using jetting action, specialized drill bit, whipstock, steerable downhole mud motor (SDMM) etc.

Directional Drilling is the science of deviating a well bore along a planned course to a subsurface target whose location is a given lateral distance and direction from the vertical. It is typically applied where the reservoir is trapped in an inaccessible location. Directional/Horizontal Drilling has many advantages that make it a widely used process. With an advancement of technology Directional Drilling has become more efficient which ultimately decreases the operational cost. There are multiple techniques of drilling directional wells such as using jetting action, specialized drill bit, whipstock, steerable downhole mud motor (SDMM) etc.

Directional and Horizontal Drilling Services by JDIL.

Jindal Drilling & Industries Limited (JDIL) is the first Indian company in providing Horizontal & Directional Drilling services in India since 2003. Besides the company has been successfully providing integrated on-line Mud Logging services to ONGC for many years.

JDIL offers the drillers a highly proven technology to drill the well correctly. Our MWD services provide a highly accurate and quality data which enable time critical decision for precise drilling in complex drilling operations.

Our focus is on achieving cost & time efficient operations, to ensure optimized directional drilling performance and precise well bore placement so as to increase Rate of Penetration (ROP) and maximize reservoir exposure.

Directional equipment features:

- Positive Pulse system, Directional Electronics, Gamma probe and surface systems for online Display of Tool face, Inclination, Azimuth and recording of Gamma plot. The MWD tool is retrievable, thus saving the Client of any liability during hostile hole conditions leading to stuck situations.

- The MWD tool is powered by high temperature lithium batteries, which allow the tool to be downhole for over 300 hrs and with a provision of one more battery to further increase downhole hours.

- Positive displacement motors (motors) with adjustable bent facility to facilitate the steering according to desired hole profile.

JDIL has its own team of experienced Directional Drillers and MWD engineers with diverse and rich experience in drilling various directional well profiles. Presently we possess more than 10 ready sets of MWD tools, more than 80 Steerable Downhole Mud Motors, about 20 Jars and about 90 Non-magnetic Drill Collars. This enables us to mobilize the tools at very short notices and serve our customers effectively. Our Client list includes ONGC, GSPC, GEO ENPRO, OILEX, JOSHI TECHNOLOGIES INTERNATIONAL, CANORO RESOURCES etc.

We has strategically located service and maintenance workshop with all modern facilities. The workshop is equipped with a Torque Master (National make) capable of complete disassembly and assembly of motors and Jars. The facility is also equipped with an overhead crane of 7 tons capacity and a complete Drilling Jar testing unit. Besides, the workshop also has sophisticated test and measurement systems to repair maintain and test MWD tools and surface equipment.

Present contracts under execution by our group - FY 2019-2020

- Oil & Natural Gas Corporation – 4 Kits

- Other E & P Companies – 1 kit (Callout basis)

- Total wells drilled in 2018-2019 – 42